In August, chipmaker Intel revealed new details about its plan to build a “mega-fab” on US soil, a $100 billion factory where 10,000 workers will make a new generation of powerful processors studded with billions of transistors. The same month, 22-year-old Sam Zeloof announced his own semiconductor milestone. It was achieved alone in his family’s New Jersey garage, about 30 miles from where the first transistor was made at Bell Labs in 1947.

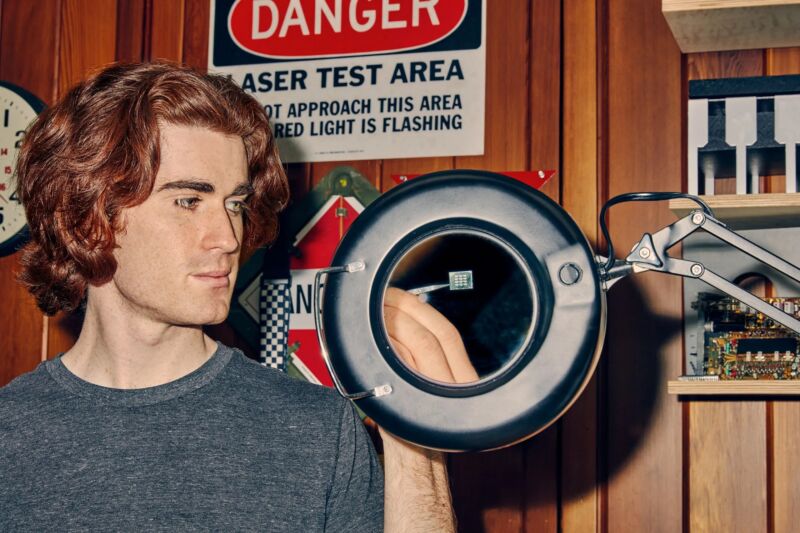

With a collection of salvaged and homemade equipment, Zeloof produced a chip with 1,200 transistors. He had sliced up wafers of silicon, patterned them with microscopic designs using ultraviolet light, and dunked them in acid by hand, documenting the process on YouTube and his blog. “Maybe it’s overconfidence, but I have a mentality that another human figured it out, so I can too, even if maybe it takes me longer,” he says.

Zeloof’s chip was his second. He made the first, much smaller one as a high school senior in 2018; he started making individual transistors a year before that. His chips lag Intel’s by technological eons, but Zeloof argues only half-jokingly that he’s making faster progress than the semiconductor industry did in its early days. His second chip has 200 times as many transistors as his first, a growth rate outpacing Moore’s law, the rule of thumb coined by an Intel cofounder that says the number of transistors on a chip doubles roughly every two years.

Zeloof now hopes to match the scale of Intel’s breakthrough 4004 chip from 1971, the first commercial microprocessor, which had 2,300 transistors and was used in calculators and other business machines. In December, he started work on an interim circuit design that can perform simple addition.

Outside Zeloof’s garage, the pandemic has triggered a global semiconductor shortage, hobbling supplies of products from cars to game consoles. That’s inspired new interest from policymakers in rebuilding the US capacity to produce its own computer chips, after decades of offshoring.

Garage-built chips aren’t about to power your PlayStation, but Zeloof says his unusual hobby has convinced him that society would benefit from chipmaking being more accessible to inventors without multimillion-dollar budgets. “That really high barrier to entry will make you super risk-averse, and that’s bad for innovation,” Zeloof says.

Zeloof started down the path to making his own chips as a high school junior, in 2016. He was impressed by YouTube videos from inventor and entrepreneur Jeri Ellsworth in which she made her own, thumb-sized transistors, in a process that included templates cut from vinyl decals and a bottle of rust stain remover. Zeloof set out to replicate Ellsworth’s project and take what to him seemed a logical next step: going from lone transistors to integrated circuits, a jump that historically took about a decade. “He took it a quantum leap further,” says Ellsworth, now CEO of an augmented-reality startup called Tilt Five. “There’s tremendous value in reminding the world that these industries that seem so far out of reach started somewhere more modest, and you can do that yourself.”

Computer chip fabrication is sometimes described as the world’s most difficult and precise manufacturing process. When Zeloof started blogging about his goals for the project, some industry experts emailed to tell him it was impossible. “The reason for doing it was honestly because I thought it would be funny,” he says. “I wanted to make a statement that we should be more careful when we hear that something’s impossible.”

Zeloof’s family was supportive but also cautious. His father asked a semiconductor engineer he knew to offer some safety advice. “My first reaction was that you couldn’t do it. This is a garage,” says Mark Rothman, who has spent 40 years in chip engineering and now works at a company making technology for OLED screens. Rothman’s initial reaction softened as he saw Zeloof’s progress. “He has done things I would never have thought people could do.”

Zeloof’s project involves history as well as engineering. Modern chip fabrication takes place in facilities whose expensive HVAC systems remove every trace of dust that might trouble their billions of dollars of machinery. Zeloof couldn’t match those techniques, so he read patents and textbooks from the 1960s and ’70s, when engineers at pioneering companies like Fairchild Semiconductor made chips at ordinary workbenches. “They describe methods using X-Acto blades and tape and a few beakers, not ‘We have this $10 million machine the size of a room,’” Zeloof says.

Zeloof had to stock his lab with vintage equipment too. On eBay and other auction sites he found a ready supply of bargain chip gear from the 1970s and ’80s that once belonged to since-shuttered Californian tech companies. Much of the equipment required fixing, but old machines are easier to tinker with than modern lab machinery. One of Zeloof’s best finds was a broken electron microscope that cost $250,000 in the early ’90s; he bought it for $1,000 and repaired it. He uses it to inspect his chips for flaws, as well as the nanostructures on butterfly wings.